In this post we discuss the swept area of a set of simple seals that surround the vanes, and compare this to the swept area of seals in a reciprocating piston cylinder.

The aim of these calculations is to compare the areas to get an estimate for how the two cylinder/piston geometries may impact the friction during motion. There are a bunch of caveats to this, for example: the frictional force is a directly proportional to the normal force acting on the surface (proportional to the pressure); in the reciprocating piston (RP) this force is almost the same around the whole piston ring, but not so in the Galin engine (GE). There are other caveats, but let us not use up the whole box of envelopes when all we are aiming to do is basically a back-of-the-envelope calculation.

Some points that we do need to write down before we begin are these:

cylinder volume of the RP and GE cylinders is the same, equal to 27cc (the dimensions of the RP and GE are given here),

seal inside the RP travels the length of the cylinder (stroke) four times between each power stroke,

four power strokes occur while the seal inside the GE travels the total volume of the chamber,

four vanes need sealing in GE,

single piston needs sealing in RP.

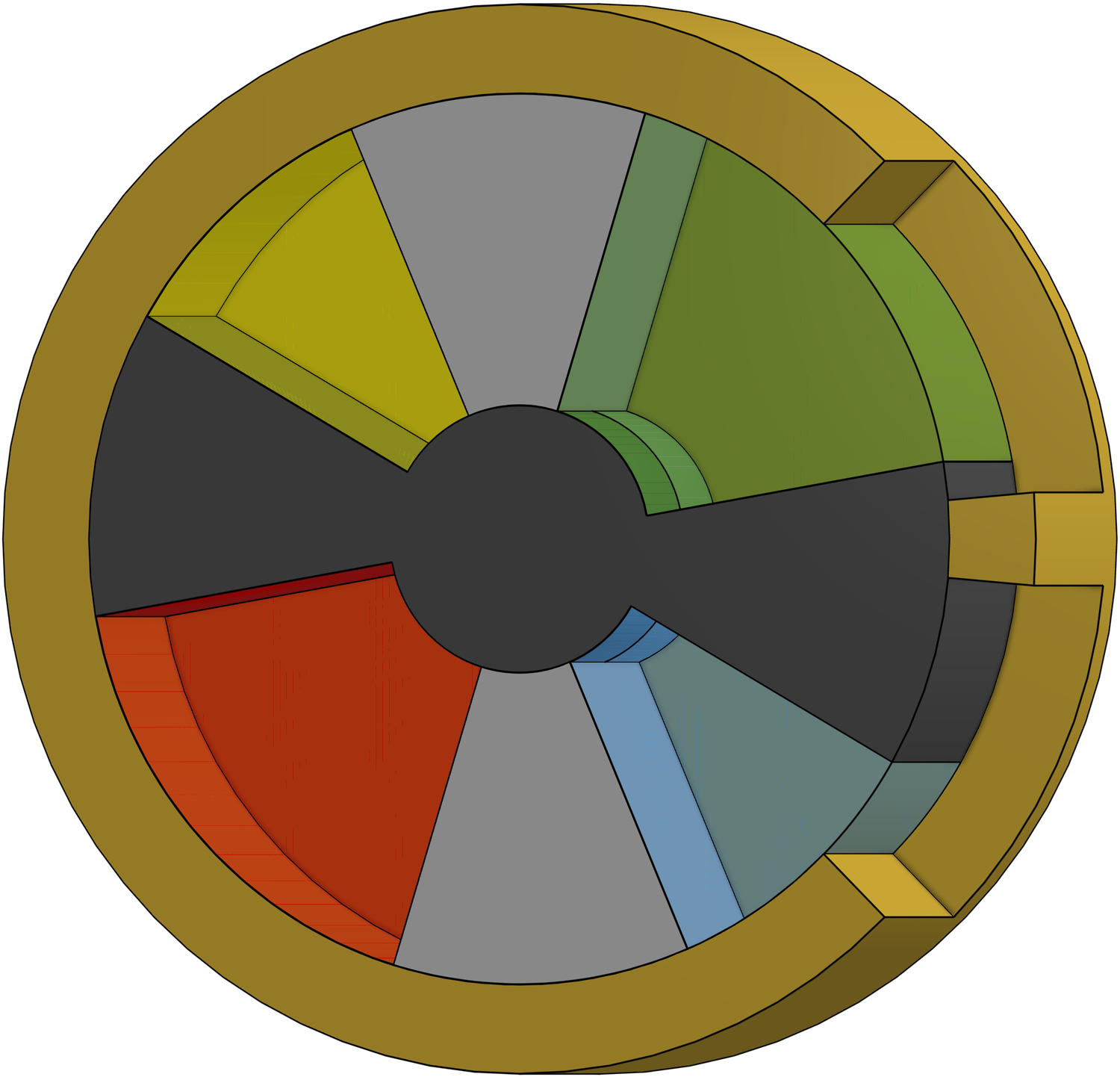

I am assuming you checked out the GitHub page and satisfied yourself that the dimensions I am going to use below for the RP and GE pistons, vanes and respective cylinders give the same swept volume of 27cc. Below is a quick summary:

Now that we have confirmed that the we are comparing engine cylinders of similar volumes and hence similar expected combustion characteristics, let us look at the surface area (SA) covered by a single piston ring seal to the SA of a seal around a GE vane.

And in GE, a seal tracing most of the vane covers a SA of:

So, how do these areas stack up? Well, straight away I breathe a sign of relief as I see that they are the same order of magnitude, so nothing crazy terrible is happening in GE, and then I compare the areas closely and see that in GE the area traced is only 13% greater - great news! More caveats to follow:

in a practical RP cylinder, the piston usually has 3 rings - so in fact the area traced will be three times higher,

by changing the dimensions of the GE chamber and vanes we can change the SA to get it smaller (or larger if need be) the dimensions chosen just happened to work out nicely.