What happens if we use Galin Engine to turn a propeller?

Hello World! In this post we will discuss mechanically loading the output shaft of Galin engine with a propeller; the unusual (i.e. non-uniform) rotation of the shaft, and compare the implications for the flow, static pressure and power required to turn a propeller versus standard uniform rotation.

TL;DR (calculations here):

volume flow: does not change,

pressure: 23% higher,

power: 70% higher,

sound power level: 6.6 dB higher,

relative efficiency: 23% lower.

Well, this is not looking too good for running a GE to turn a propeller.

There are two configurations possible of Galin engine (GE); first being a configuration where each shaft (thereby each set of vanes) is under direct control by an electrical machine (EM), second where a flywheel is attached to one shaft (and spins at a constant speed) meanwhile the second shaft is under direct control by an EM. In this post we will explore the implications on the flow, static pressure and power of the second arrangement. Why? Because the speed profile of the shaft is non-uniform in such a configuration, and has not been studied before, and is thereby inherently interesting. It would also be interesting to understand if there are any non-uniform speed profiles that optimise any of the parameters that we will assess - but that’s a question we will leave for later.

Now, to my understanding, it is notoriously difficult to derive absolute numbers for flow, static pressure, power consumption, etc., for a fan at a given speed, diameter and shape of propellers. However, there are “FAN LAWS” which relate these values to each other. That is, if you have the flow at one speed, the “FAN LAWS” allow you to calculate the flow at a different speed and so forth. These relationships are what we will use, as well as some basic averaging calculations to derive the effective values of various parameters. Here is a cheat sheet for of these laws. And here are our calculations.

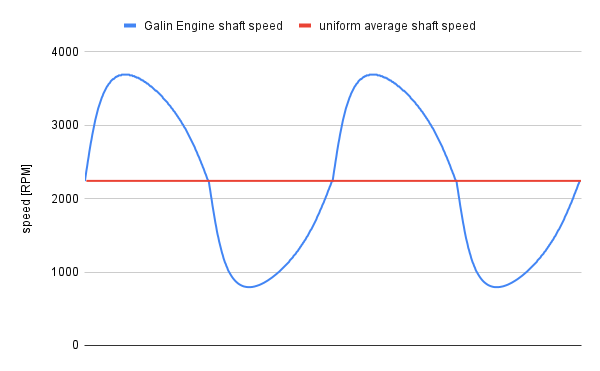

Using as our speed profiles, the speed profile the output of our Python script for a 30cc (compression ratio of 9) Galin engine (see figure below) we get the following relationship between the fan parameters:

Conclusions:

As much as it would please me to have a Galin engine driven fan be relatively more efficient, less power hungry, deliver higher flow, higher pressure, all at a lower noise level, alas, that is not the case. Reality is, in fact, much more pedestrian, and explains why running fans at non-uniform speed profiles is not a done thing.