We examine in some detail the operation and operational efficiency of a commercially available genset (Honda EU22i) and compare to a Galin Engine equivalent.

What’s a genset? A genset/generator is a device that converts the heat energy of hydrocarbons (usually petrol, diesel) into electrical energy (usually AC). Commonly these devices comprise an internal combustion (IC) engine whose output shaft directly drives an alternator. The older varieties of gensets required that the engine provide mechanical power at a precise RPM so as to produce electricity at an output frequency (50 or 60 Hz). The relationship between shaft speed and output electrical frequency is given by: \(f_{elec}= \frac{P}{2}\cdot\frac{N}{60},\) where \(f_{elec}\) is the electrical output frequency, \(P\) is the alternator pole count, \(N\) is the RPM speed of the shaft. This required speed is/was not always optimal for the engine and hence, the system - out of the box - incurs an efficiency loss due to operating away from the point at which max torque is generated. This may be considered a small problem, however, we’ll quantify it below and find out what impact it has.

Traditional gensets were made to only run at that one RPM (3000 for 50 Hz, and 3600 for 60 Hz output AC power) this means that the power supplied by the genset is always the same regardless of the required power draw, another source of inefficiency. And if you don’t get the speed regulation quite right, then there is frequency drift in the output, which could be harmful to plugged in electronics. New types of gensets - inverter gensets - are on the market which adjust the speed of the engine up/down depending on the detected load requirements and have electronics in place to convert the AC output (possible far from 50/60 Hz) to DC and then back to AC for a cleaner frequency output, but also to only produce the requested power.

Of all the genset manufacturers out there, Honda is top-notch. Why? Because they provide the most detailed, easy to access datasheets for both their engines and generators. Thank you Honda.

The EU22i is a petrol powered inverter genset that consumes petrol to produce 240V 50 Hz AC electricity at a maximum consumable rate of 1.8kW, i.e. max current draw is 7.5 A. The genset has the Honda GX120 engine. From the genset specifications we read that when it is operating it consumes approximately 1.14 L/hr, has a 3.6 L capacity tank, and can operating continuously for 8.1 hrs at 1/4 output. But, 3.6 L / 8.1 hrs = 0.44 L/hr —> x 4 = 1.78 L/hr, not 1.14 L/hr. What’s going on? There are some non-linear effects here.

Let us go back to the basics and see if we can use the basic data provided in the datasheet to tease out the efficiency of the genset, engine and alternator.

First, let us start with the engine’s fuel consumption. Let us (for now) ignore the fact that the genset has an inverter, and just assume that the engine is at full load and spins at an RPM of 3000 to generate an electricity at a 50 Hz frequency. The engine is a 121cc, single cylinder petrol engine, meaning that when running at 3000 RPM it will (theoretically speaking) consume 121 mL of a stoichiometric mixture of oxygen and petrol 25 times per second (25 times, not 50 times because there are two revolutions of the shaft between each power stroke). We can calculate the volume of petrol consumed per hour as:

stoichiometric mixture of oxygen to fuel is 14.7:1 (by mass),

air density at 15C: \(1.225 kg/m^3\),

petrol density at 15C: \(750 kg/m^3\),

therefore, the stoichiometric mixture of oxygen to fuel by volume (at 15C) is: \(12 m^3 : 0.0013 m^3 \) or ~ 9000 : 1.

121 mL / 9001 x 1 = 0.013 mL of petrol consumed 25 times per second, or 1.21 L/hr.

Our calculated fuel consumption per hour is a bit higher than the one provided in the spec sheet. Assuming we got the densities correct, what does this mean if we consider that the actual fuel consumption at full output power is in fact 1.14 L/hr? It means that either the engine is not actually spinning at 3000 RPM, but somewhat slower (actually running at about 2827 RPM) or that the mixture is not in fact stoichiometric, the engine is running lean (actual ratio is 9552:1 by volume, or 16.0:1 by mass) or a combination of both these things.

Let us assume that the engine is in fact consuming 1.14 L/hr. The engine has a compression ratio of 8.3, which gives us a maximum thermal efficiency of: $$ \eta = 1 - \frac{1}{r^\left( \gamma-1 \right)} $$ where \(\eta\) is the thermal efficiency coefficient, \(r\) is the compression ratio, and \(\gamma\) is the specific heat ratio of the gases (about 1.4). The maximum efficiency of a heat engine with a compression ratio of 8.3 is 57%. (This efficiency calculation is the absolute maximum, and can only be approached by practical IC engines which have frictional forces, incomplete combustion, and a plethora of other real-world effects to contend with.) Keeping this is mind, if the engine consumes 1.14 L/hr, and the energy content of fuel is 34 MJ / L, the engine should output a 6.14 kW. However, the engine actually outputs ~2.25 kW so it is 37% efficient. The genset actually outputs 1.8 kW, and hence, we can calculate the efficiency of the alternator (together with the inverter, and other electronics) at: 80%. The overall system from input to output is 29% efficient (accounting for the maximum possible theoretical thermal efficiency of the combustion process).

As an aside - if we were able to invent a combustion process that would be more efficient, and we could extract up to 10.8 kW from combusting fuel at a rate of 1.14 L/hr. In this scenario our genset is only 17% efficient.

Looking at the torque vs speed, and power vs speed curves provided by Honda for their GX120 engine we see that the maximum torque (7.3 Nm) output occurs at about 2500 RPM - this is probably the RPM at which a stoichiometric mixture can have time to fully combust, and the crank-shaft mechanism can extract the maximum energy from combustion. However, as we are operating away from this optimal RPM, the engine will suffer an efficiency loss. If we assume a linear relationship between torque output and combustion efficiency, we note that at 3000 RPM we get about 7.2 Nm (if we squint hard and trust that the value of 7.3 Nm given at 2500 RPM is correct - although the torque curve is hard to believe. Maybe its is so flat because the frictional forces of the engine play a large role in the torque output?). Hence, we are suffering an efficiency loss of about 2%.

A genset can be considered a battery. In this case, the genset is a 3.6L/(1.14 L/hr) x 1.8 kW = 5.7 kWh battery, with a maximum discharge capacity of: 1.8 kW. The nice feature about this battery is that it can be recharged almost instantly. However, this particular battery has additional consumables such as oil, air filters, etc. This genset weights 25 kg (full fuel tank, and oil reservoir) and costs in the range of NZ$2900. (We can, in practice, increase the fuel tank to any reasonable size, and thereby increase the capacity of this battery.)

As a point of comparison, a 3.6 kWh lithium ion battery weights 45 kg, costs ~NZ$7,200. The energy conversion efficiency of this battery technology in theory is 99% (at least that is what the internet tells me). But, if we look online at various reports of how long it takes to charge this device, we see that it takes about 3 hrs to charge at an outlet with 1800 W power output. This indicates a charging efficiency of 67% (3600/1800/3 x 100). Let us assume that the discharge efficiency is 90%, this is an overall system efficiency of 60%. (Should I mention the efficiency of the grid in generating electricity?) A good thing about this battery is that it is comparatively silent (except for some fan noise), and does not have additional consumables.

Galin Engine Genset:

Now, the interesting part :)

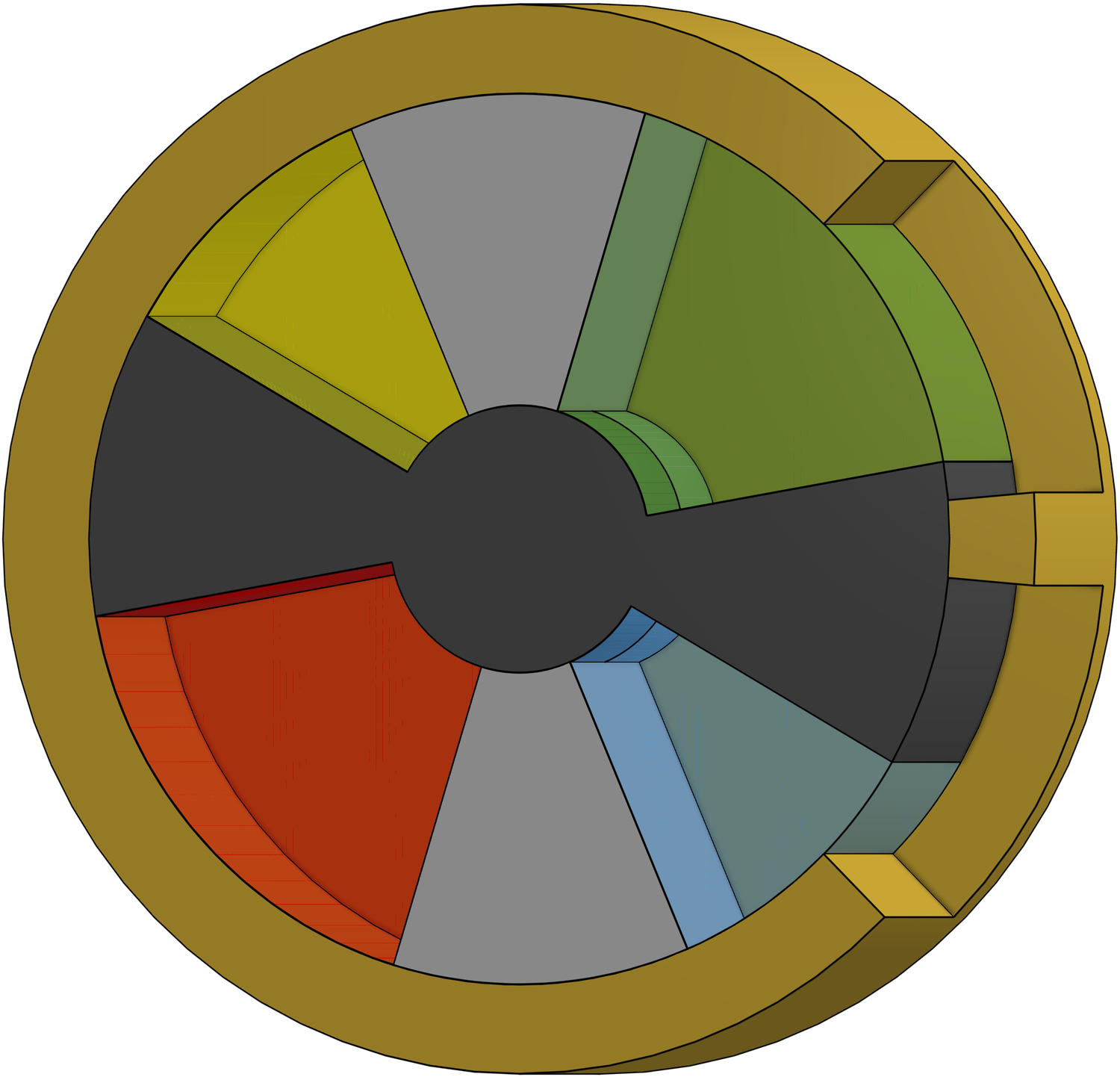

The Galin engine based genset schematically looks like this (where “RV” means rotary-vane internal combustion engine, and “M” are the PMSM or reversible electrical machines):

Let us study various characteristics of a GE genset. First, the bad news: we will assume that the combustion process (being the 4-stroke Otto cycle) will be of the same theoretical efficiency. Thereby, we are out-of-the-box limiting ourselves to a maximum efficiency of 57%. Additionally, we assume a PMSM efficiency of 95%, and a DC-AC conversion efficiency of 95%, hence, the total maximum possible system efficiency is: 0.57 x 0.95 x 0.95 = 0.51. In order to achieve a 1.8 kW output power: at the inverter we need 1.9 kW, at the PMSM 2.0 kW, and 3.5 kW going into the rotary vane engine.

A GE has 8 power strokes for every power stroke in a reciprocating piston engine (which has 1 power stroke for every 2 shaft revolutions). To get the same power output we do not need the same cylinder volume as in the above genset, we can get away with a quarter of the volume: 121 / 4 = 30 cc. Additionally, we will not be using a 80% efficient alternator for converting mechanical energy to electrical, and so we can decrease the volume slightly to 25 cc. Given this, the combustion chamber for Galin engine has the following specifications:

compression ratio: 8.3 (if we assume a vane angular width of 40 degrees, we calculate the minimum angle of the combustion chamber to be 10.75 degrees)

volume (min + max): 25 cc

Plugging these numbers into our Python script, we get the following Galin engine output characteristics:

r = 12 mm,

R = 36 mm,

d = 24 mm,

\(\theta\) = \(40^\circ\),

\(t_s\) = 6.2 ms (stroke time),

\(T_{out}\) = 15.5 Nm,

\(\omega_{ave}\) = 2420 RPM.

\(P_{out}\) = 3.4 kW.

Below we plot the speed, and torque requirements for the electrical machines over a time period of 4 strokes, i.e. a full 360 degree rotation of the vanes. The product of torque and speed gives us the power requirements for the electrical machine.

Looking at the figure to our left we note that the electrical machines on the two shafts alternate between motoring and generating every stroke, and that the power requirements for generating and motoring are not equal. This makes sense - we are in the business of generating power after all. The electrical machines need to be able to absorb energy at a rate of 6.8 kW, and generate energy at a rate of 4.2 kW, all the while pulling/pushing respectively with a torque of 15.5 Nm. Therefore, we size the electrical machines as:

\(P_{max}\) = 7 kW,

\(\omega_{max}\) = 4000 RPM,

\(T_{max}\) = 17 Nm.

These requirements are not wild, and here are a couple websites which provide motors that will meet our requirements:

Galin Generator weight:

Given the above dimensions for the combustion chamber, together with the electrical machines (weighting about 2kg each) it is not out of the question that a Galin Generator weight would come in under 25 kg.

Galin Generator size:

Because we are sizing Galin generator for the same power output as the Honda genset, and because a Galin generator has 8 power strokes for every 1 power stroke in a reciprocating piston engine, we have a much smaller combustion chamber. The size of the electrical machines is also quite modest (close to the combustion chamber size). However, we have not considered the cooling system which may be necessary. Overall, it is likely that a Galin generator will be close to the same size as the Honda genset.

Galin Generator vibration:

The combustion chamber is perfectly balanced, with no off-centre components, hence the vibrations that are experienced by a crank-shaft mechanism are not present. Additionally, unlike the piston inside a reciprocating piston engine which experiences acceleration, deceleration, stop, reversing of direction etc, the vanes inside the Galin generator are always rotating in the same direction - another reason to anticipate lower overall vibrations of the system.

Galin Generator noise:

The two main sources of noise from an internal combustion engine are: combustion noise, and piston slap. These two sources are comparable in their contribution to the total noise level. There is no piston slap in a Galin generator, but there are 8 combustion strokes for every 1 combustion stroke of a reciprocating piston engine. I’m not sure how to add the amplitudes of the noise just yet.

Galin Generator BOM:

Imagine ripping out the reciprocating piston pump, with the crankshaft, camshaft, valves etc, and replacing that whole complicated mechanism with:

electrical machines x 2,

combustion chamber,

position sensors x 2,

motor controllers,

battery,

DC / AC converter (IF we are actually wanting AC power out - as most appliances are switching to DC, demand for DC electrical energy is increasing).

Galin Generator cost:

Given the mechanical simplicity of a Galin generator - where most of the complexity has been moved into the software of the control system, there is reason to suppose that the Galin generator will cost the same as a Honda genset. The pertinent point here is that the mechanical constraints present in a reciprocating piston pump are not present in a Galin pump. The Galin pump has a software controlled crankshaft, i.e. the ratio of compression, the time to expand are determined by positioning of the vanes which are software controlled.