Rethinking pumps for applications in fluid delivery, compressors, and engines.

Is this some marketing jargon? Why would we want to ‘rethink’ pumps? Pumps are the workhorses of many industries. Replacing existing pumps can have serious consequences:

Proven Reliability: Traditional pump designs have been tested and proven over decades, ensuring reliability and predictability in performance. Introducing new concepts carries the risk of unforeseen failures that could disrupt operations in critical industries.

Standardization and Compliance: Many industries rely on standardized equipment to meet regulatory and safety compliance. Rethinking pump designs might require a long process of re-certification and could face resistance due to established industry norms and regulations.

Cost and Investment: Significant investments have been made in existing pump infrastructure. Transitioning to a new design could involve substantial costs not only in acquiring new pumps but also in retraining staff, adapting maintenance protocols, and modifying systems, which may not deliver proportional benefits.

Complexity and Maintenance: Innovative pump designs, especially those involving complex software controls, might introduce additional layers of complexity. This can increase maintenance requirements and potentially complicate troubleshooting, thus leading to higher operational costs and longer downtimes.

Unintended Consequences: Rethinking something as foundational as pump design can lead to unintended side effects, such as compatibility issues with existing systems or unforeseen operational challenges that negate the intended benefits.

Market Adoption Hurdles: Introducing radically new concepts could face adoption barriers where industries prefer incremental improvements over radical changes, especially in sectors where downtime or failure has high stakes.

Focus on Enhancement Instead: Instead of a complete rethink, efforts might be better invested in enhancing current technologies for improved efficiency or integrating smart technologies, which can provide benefits without the risks associated with a complete overhaul.

These arguments are all sound and correct. Such arguments are always faced by new technological breakthroughs. For example, at the time when the engine was first built and proposed as an alternative to the humble working horse. All but the second point above could be used to argue that horses should not be replaced by engines. In fact, when engines were first conceived and used, they had a a lower energy conversion efficiency of horses.

Why did new, unproven technology find success?

Because it allowed humans to achieve things previously not possible.

It was not that engines could be drop in replacements for horses, or were more reliable, cheap and easy to maintain (they certainly were not). It was that when engines were installed, work could continue around the clock, in many different climates etc. Eventually engines surpassed horses in reliability, operating cost, complexity and maintenance.

How about light bulbs? We tend to have a very short cultural memory - but try to imagine yourself in a house without electricity, using candle light to function when the sun went down. What would you say to a proposed new technology called the “light bulb”?

it isn’t proven - I have all these candles that work instantly when I light them, and they last for hours,

thicker candles last longer, thinner candles shorter, how do I know how long any light bulb I purchase will work? There are no standards around their operating life,

these light bulbs are super expensive and hard to get - where do I even buy replacements when I need them?

these light bulbs are complex, and impossible to maintain, and I do not have electricity supplied to my house, how can I even use them?

what happens when the glass breaks? if the glass explodes, it might also lead to blindness, burns or other serious injury. What if my children get hurt?

there is no way the market will adopt this technology - it is only possible with electricity provisioned to every house, and good luck getting that done!

why don’t you focus on candle wax that will last longer instead? perhaps there are additives that increase wax burn time, and produce less soot. Now there is a good idea, you’ll be rich in no time!

And yet, light bulbs did make it as a technological advancement. Why? Because they allowed humans to achieve things previously not possible. But enough about history…

Does Galin technology allows humans to achieve things previously not possible? Yes.

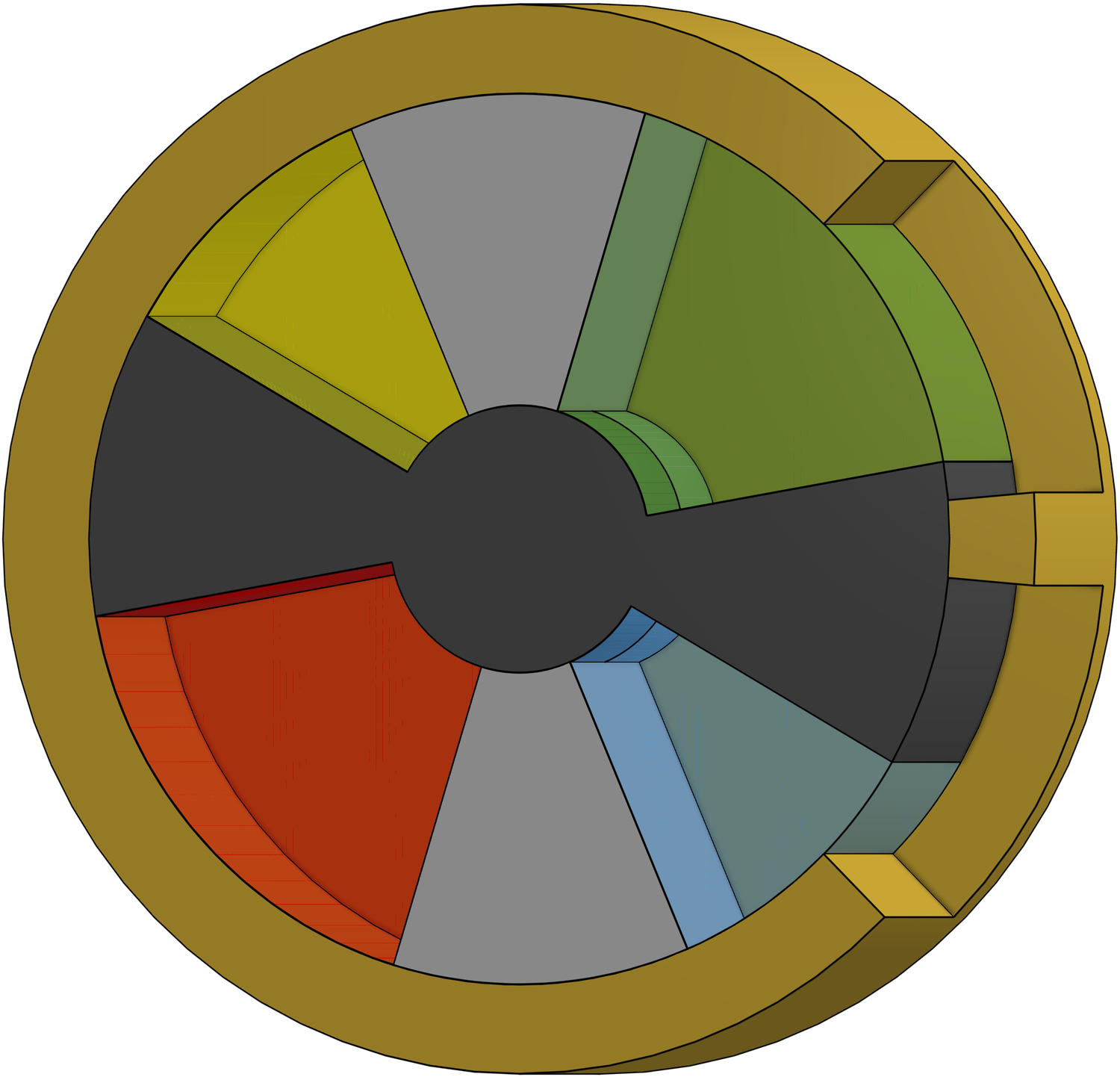

Galin Pump (with applications in fluid pumps, compressors and engines) is a software controlled pump. The chamber volume, speed of rotation is completely under software real-time control. This is not possible with existing pumps.

Traditional pumps all have the following components in common:

chamber with inlet and outlet ports,

shaft to accept linear, or more commonly, rotary motion,

often with inlet/outlet valves.

The variety of pump designs is staggering; there are over 1000 different functional designs, with around 50-100 well established types. The large number variations on the theme tell the story of our search in the design space to find a pump to fit a particular niche application better than what exists already - we are forever searching for flexibility in operating parameters. Bounded by the above listed design constraints, even with the 1000s of existing variations, and more in R&D departments across all pump manufacturers, industry is currently facing the following struggles:

Mechanical Complexity When Adjusting Flow or Volume Delivery Is Required

Adjusting flow rates or volumetric delivery necessitates mechanical complexity, involving intricate components and mechanisms that increase costs, reduce reliability, and complicate maintenance procedures.

Limited Flexibility; Function Predetermined by Static Design

The system offers limited flexibility because its functionality is predetermined by static design, restricting its ability to adapt to changing operational needs or accommodate different applications without modifications.

Analog Adjustment Methods

Adjustments are performed through analog means, which may lack the precision, responsiveness, and ease of use provided by digital control systems, potentially leading to inefficiencies and inconsistent performance.

Limited Instrumentation for Maintenance and Monitoring

More instrumentation is necessary for maintenance and monitoring of critical factors like cavitation. It is challenging and expensive to perform proactive upkeep, detect issues, and ensure efficiency and longevity.

The future is increased automation, improved process control, higher energy efficiency, connectivity between components, and real-time monitoring of component operation for system performance control, and predictive maintenance. We can get there by focusing on enhancements, and retrofitting existing systems with connected IoT enabled sensors to make our “dumb” equipment “smart”, or we can rethink pumps from the ground up, and explore the new technological architecture of a software enabled pump - Galin Pump.